How to Maintain Aerial Work Platforms for Long-Term Use

Aerial work platforms, also known as Mobile Elevated Work Platforms (MEWPs), are significant investments for any business.

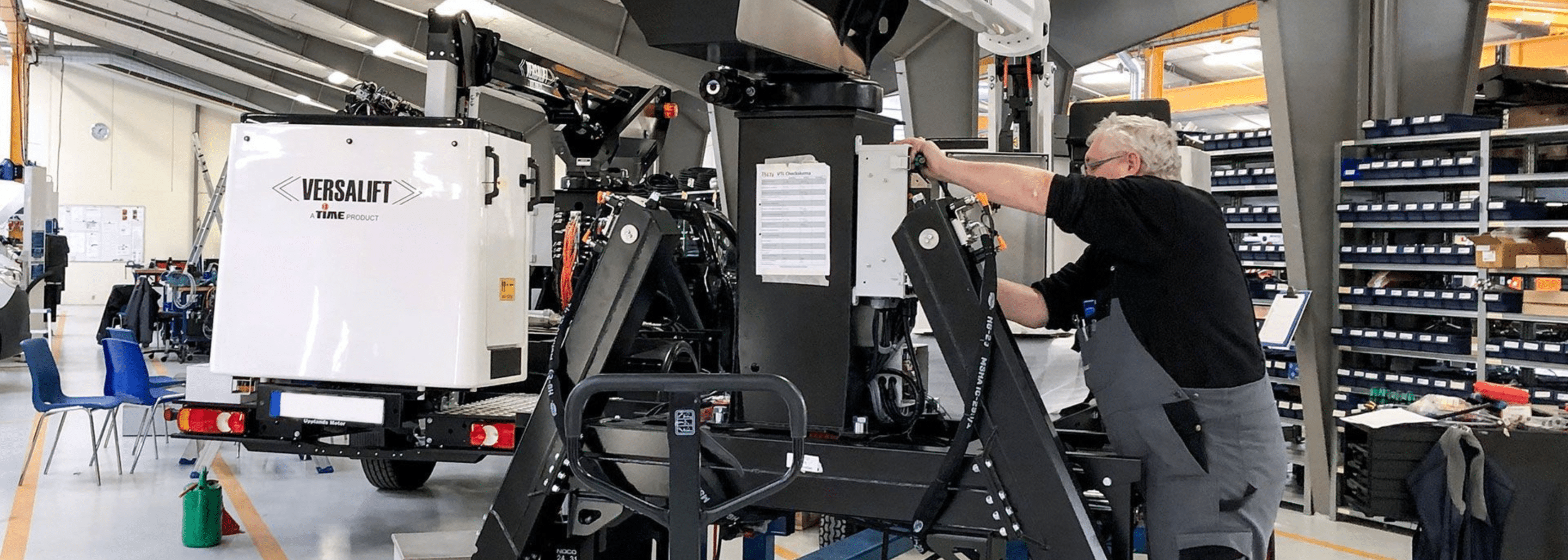

Whether you’re in rental, arboriculture, utilities, telecoms, security, or any other industry that relies on safe working at height, proper maintenance is crucial for maximising the lifespan and performance of your Versalift access platform.

This blog post outlines 10 essential maintenance practices that will help you keep your MEWP in top condition for years to come.

1. The Importance of Regular Maintenance

Regular maintenance is not just about keeping your MEWP looking good; it’s about ensuring safety, reliability, and long-term cost savings. Neglecting maintenance can lead to:

Increased Downtime: Unexpected breakdowns can disrupt operations and lead to costly delays.

Reduced Performance: Poorly maintained equipment may not perform at its optimal level, reducing efficiency.

Safety Hazards: Malfunctioning components can create safety risks for operators and those working nearby.

Shorter Lifespan: Without proper care, your MEWP’s lifespan can be significantly reduced, requiring premature replacement.

Higher Repair Costs: Addressing minor issues early can prevent them from becoming major, expensive repairs down the line.

2. Daily Pre-Use Inspections

Before each use, a thorough pre-use inspection is absolutely essential. This should be a non-negotiable part of your operating procedure. Check the following:

Structural Components: Inspect the boom, platform, chassis, and outriggers for any signs of damage, cracks, or corrosion.

Hydraulic System: Check hoses, connections, cylinders, and fluid levels for leaks or damage.

Control System: Verify that all controls, including joysticks, switches, and the emergency stop, are functioning correctly.

Safety Features: Ensure that harnesses, lanyards, and other safety equipment are in good condition and properly attached.

Tyres and Wheels: Check tyre pressure, tread depth, and wheel condition.

Fluid Levels: Check engine oil, hydraulic fluid, coolant, and other essential fluids.

Battery (if applicable): Inspect battery terminals for corrosion and ensure they are properly charged.

3. Scheduled Maintenance

Versalift provides detailed maintenance schedules for each of its MEWP models. These schedules outline specific maintenance tasks that should be performed at regular intervals, such as:

Lubrication: Greasing moving parts to reduce friction and wear.

Filter Changes: Replacing air, oil, and hydraulic filters to maintain system cleanliness and performance.

Fluid Changes: Changing engine oil, hydraulic fluid, and other fluids according to recommended intervals.

Inspection and Adjustment: Inspecting and adjusting critical components, such as brakes, chains, and belts.

Component Replacement: Replacing worn or damaged parts before they cause further problems.

Adhering to these scheduled maintenance tasks is crucial for preserving your MEWP’s performance and longevity.

4. Battery Maintenance For Electric Models

For electric MEWPs, proper battery maintenance is essential. Follow these tips:

Regular Charging: Charge batteries after each use and avoid letting them completely discharge.

Correct Charger: Use the correct charger for your battery type.

Terminal Cleaning: Clean battery terminals regularly to remove corrosion.

Battery Testing: Have batteries tested periodically to assess their health and capacity.

5. Hydraulic System Maintenance

The hydraulic system is the heart of your MEWP. Proper maintenance is crucial for smooth and reliable operation.

Regular Inspections: Inspect hoses, connections, cylinders, and pumps for leaks or damage.

Fluid Changes: Change hydraulic fluid according to the manufacturer’s recommendations.

Filter Changes: Replace hydraulic filters regularly.

Leak Repairs: Address any leaks promptly to prevent further damage.

6. Tyre Maintenance

Proper tyre maintenance is essential for safety and performance.

Tyre Pressure: Maintain correct tyre pressure as specified by the manufacturer.

Tread Depth: Check tread depth regularly and replace tyres when they are worn.

Tyre Damage: Inspect tyres for cuts, punctures, or other damage.

7. Cleaning and Storage

Keeping your MEWP clean and storing it properly can significantly extend its lifespan.

Regular Cleaning: Clean the MEWP regularly to remove dirt, debris, and grime.

Protective Storage: Store the MEWP in a dry and sheltered area when not in use.

Corrosion Prevention: Apply corrosion inhibitors to protect metal parts from rust.

8. Tracking Maintenance History

Maintaining accurate records of all maintenance activities is crucial. This includes:

Maintenance Logs: Keeping detailed records of all inspections, repairs, and maintenance tasks.

Service History: Tracking the service history of the MEWP, including dates, mileage, and parts replaced.

Warranty Information: Keeping records of warranty information for all components.

9. Professional Servicing

While some maintenance tasks can be performed in-house, sometimes you need to rely on qualified technicians for more complex repairs and servicing. This ensures that the work is done correctly and that genuine parts are used.

10. Operator Training

Proper operator training is essential for responsible use and preventing damage to the MEWP. Trained operators are more likely to:

- Conduct thorough pre-use inspections.

- Operate the MEWP safely and within its limitations.

- Identify potential problems early on.

- Report any issues to maintenance personnel.

Ready to maximise the lifespan of your Versalift MEWP?

Versalift offers comprehensive after-sales support and maintenance services to help you keep your equipment in top condition. Contact us today to learn more about our service plans and how we can help you protect your investment.

FAQs

How often should I service my aerial work platform?

The frequency of servicing depends on the manufacturer’s recommendations, the intensity of use, and the specific operating environment. Consult your Versalift owner’s manual for the recommended service intervals for your model. Regular scheduled maintenance is crucial for preventing breakdowns and ensuring long-term reliability.

What are the most common maintenance issues with aerial work platforms?

Common maintenance issues include hydraulic leaks, battery problems (for electric models), tyre wear, control system malfunctions, and structural damage. Regular pre-use inspections and scheduled maintenance can help identify and address these issues early on.

Can I perform all maintenance tasks myself?

While some basic maintenance tasks, such as pre-use inspections and cleaning, can be performed in-house, more complex repairs and servicing should be entrusted to qualified technicians. This ensures the work is done correctly, genuine parts are used, and it maintains the warranty on your equipment. Attempting complex repairs without the proper training and tools can lead to further damage and safety hazards. It’s always best to consult with a Versalift authorised service centre for any major repairs or component replacements.

Liked this blog? Share it!

Follow us for our latest news, advice and products.