10 MEWP Safety Tips for Arborists

Working at height is a fundamental part of arboriculture.

Mobile Elevated Work Platforms (MEWPs), also known as cherry pickers or aerial lifts, have become indispensable tools for arborists, offering access to tree canopies and assisting with efficient tree care.

However, using MEWPs in tree work presents unique challenges and safety considerations.

This blog post outlines 10 essential safety tips for arborists using MEWPs, helping to minimise risks and ensure a safe working environment.

1. Thorough Risk Assessment

Before any tree work begins, a risk assessment is vital. This assessment should identify all potential hazards associated with the specific task, the work environment, and the MEWP itself. Consider factors like:

Tree Species and Condition: Is the tree stable? Are there any dead or weak branches? How will the tree’s structure affect MEWP positioning?

Ground Conditions: Is the ground level and stable enough to support the MEWP? Are there any underground utilities or obstacles?

Weather Conditions: Wind, rain, and extreme temperatures can significantly impact MEWP stability and operator safety.

Surrounding Environment: Are there power lines, buildings, or public access areas that need to be considered?

Emergency Procedures: What is the plan in case of an accident or equipment malfunction?

2. Choosing the Right MEWP for the Job

Not all MEWPs are created equal. Selecting the appropriate type of MEWP for the specific task and environment is crucial. Consider factors like:

Reach and Height Requirements: Ensure the MEWP can safely reach the required working height and access all parts of the tree.

Terrain: If working on uneven or sloping ground, choose a MEWP with suitable all-terrain capabilities and stabilisers.

Manoeuvrability: In confined spaces or areas with limited access, a compact and agile MEWP is required.

Weight Restrictions: Be aware of the MEWP’s weight limitations and ensure the ground can support it.

Insulation: If working near power lines, an insulated MEWP is a must.

3. Pre-Use Inspections

Before each use, a thorough pre-use inspection of the MEWP is essential. This includes checking:

Wear and Tear: Look for any signs of damage, cracks, or corrosion on the boom, platform, and chassis.

Hydraulic Systems: Inspect hoses, connections, and fluid levels for leaks or damage.

Control Systems: Verify that all controls are functioning correctly, including the emergency stop.

Safety Features: Check that harnesses, lanyards, and other safety equipment are in good condition and properly attached.

Tyres and Wheels: Ensure they are inflated to the correct pressure and in good condition.

4. Operator Training and Certification

Operating a MEWP safely requires proper training and certification. Ensure that all operators are trained and familiar with:

MEWP Operation: Understanding the specific controls and features of the MEWP being used.

Safety Procedures: Following established safety protocols and best practices.

Emergency Procedures: Knowing how to respond in case of an accident or equipment malfunction.

Legislation and Regulations: Being aware of relevant health and safety regulations. IPAF training is widely recognised and recommended.

5. Personal Protective Equipment (PPE)

Appropriate PPE is crucial for arborists working at height. This includes:

Harness and Lanyard: A full-body harness and lanyard are essential for fall protection.

Helmet: Protecting the head from falling objects and impacts.

Safety Footwear: Providing grip and protection for the feet.

Eye Protection: Shielding the eyes from debris and branches.

Gloves: Protecting the hands from cuts and abrasions.

High-Visibility Clothing: Ensuring the arborist is visible to others.

6. Safe Positioning and Platform Stabilisation

Proper positioning and stabilisation of the MEWP are crucial for safe operation. This involves:

Level Ground: Whenever possible, position the MEWP on level and firm ground.

Stabilisers: Use outriggers to ensure the MEWP is stable and secure.

Distance from Trees: Maintain a safe distance from the tree trunk and branches to avoid collisions.

Tree Movement: Be aware that trees can move in the wind and adjust the access platform’s position.

7. Working Safely Around Power Lines

Working near power lines presents huge risks to arborists. Take the following precautions:

Identify Power Lines: Locate and identify all power lines in the vicinity before starting work.

Maintain Safe Distance: Keep a safe distance from power lines, as specified by regulations.

Insulated MEWP: Use an insulated MEWP when working near power lines.

If work needs to be carried out close to power lines, consult with the utility company for further guidance.

8. Communication and Teamwork

Clear communication and effective teamwork are essential for safe aerial platform operation.

Clear Signals: Establish clear hand signals or communication protocols between the operator and ground crew.

Designated Spotter: Have a designated spotter on the ground to monitor the MEWP and surrounding area.

Regular Communication: Maintain regular communication between the operator and ground crew.

9. Emergency Preparation

Despite all precautions, accidents can still happen. Being prepared for emergencies is key.

Familiarise yourself with emergency procedures, including how to lower the MEWP in case of a malfunction.

Have a first aid kit readily available.

Create a rescue plan in case of a fall or other emergencies.

10. Ongoing Training and Reviews

MEWP safety is an ongoing process. Regular training and review of safety procedures are essential for continuous improvement and keeping up with new health and safety regulations.

Refresher Training: Attend refresher training courses to stay up-to-date on best practices.

Safety Audits: Conduct regular safety audits to identify potential hazards and improve safety procedures.

Past Accidents: Share lessons learned from previous incidents or near misses to prevent future accidents, showing your team the importance of safety first.

Do you need training?

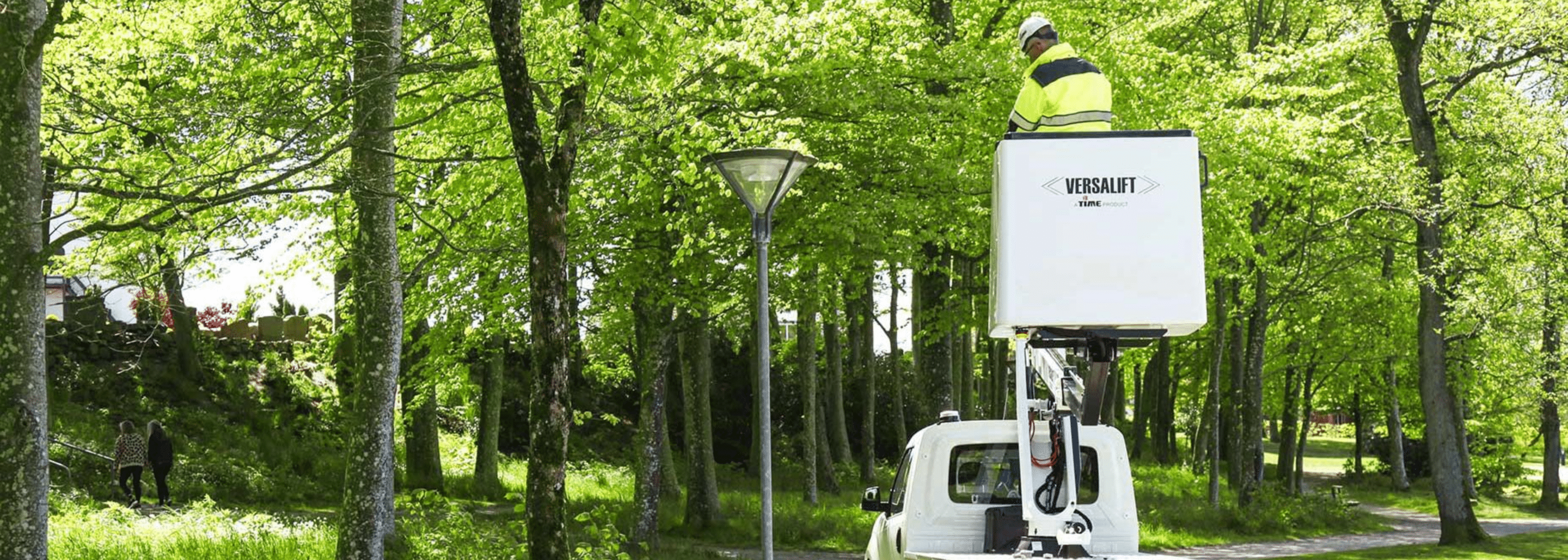

At Versalift, our qualified instructors ensure that your staff experience quality training, direct from the platform manufacturer.

Training can be given on-site at your local dealership using our latest facilities, or at your own premises. Find your local dealership to see the training courses on offer (includes IPAF training).

By following these 10 MEWP safety tips, arborists can significantly reduce the risks associated with working at height and create a safer working environment for themselves and their colleagues.

Remember, safety is everyone’s responsibility.

Ready to work safely in arboriculture?

Versalift offers a wide range of high-quality, reliable vehicle-mounted height access platforms designed to meet the specific needs of arborists. From compact and agile lifts for confined spaces to robust and powerful machines for challenging terrain, we have the perfect solutions for your tree care operations.

Explore our range of Versalift MEWPs today and discover how we can help you work safer and smarter.

FAQs

What qualifications do I need to operate a MEWP as an arborist?

While specific regulations can vary by region, it’s crucial to receive proper training and certification before operating a MEWP. IPAF (International Powered Access Federation) training is widely recognised and recommended. This training covers safe operation, pre-use inspections, emergency procedures, and relevant legislation. Always check local regulations for specific requirements.

What type of MEWP is best suited for arboriculture work?

The best MEWP for arboriculture depends on the specific job and environment. Consider factors like the tree’s height and accessibility, ground conditions, and potential obstacles. Compact and agile MEWPs are often preferred for confined spaces, while telescopic or articulating booms offer greater reach. Insulated MEWPs are essential when working near power lines. A thorough risk assessment is crucial to determine the most appropriate MEWP.

How often should MEWPs be inspected?

MEWPs should be inspected before every use. This pre-use inspection should include checking structural integrity, hydraulic systems, controls, safety features, and tyres. In addition to pre-use checks, regular thorough examinations by a competent person are also required by law. Consult the manufacturer’s recommendations and local regulations for the frequency and scope of these thorough examinations.

Liked this blog? Share it!

Follow us for our latest news, advice and products.